The EIA believes that fossil fuel-based thermal power plants will remain an important component of a reliable electricity supply until at least 2050. Financing for gas turbine power-plants continue to operate around the world as they use available fossil fuels (coal, natural gas, petroleum products) to provide cheap energy to a growing economy.

With the rise of renewables, they will continue to stabilize the power system 24/7 regardless of wind speed or solar radiation.

These facilities are helping to close the gap that arises between electricity demand and the fluctuating renewable energy generation.

The disadvantage of this type of power plant is its rather low efficiency (about 40%).

Viola Funding Limited offers a full range of financing for gas turbine power-plants, including the following:

• Project financing.

• Conducting a pre-investment assessment.

• Engineering design of a gas turbine power plant.

• Purchase of equipment from the world’s leading manufacturers.

• Civil engineering and professional equipment installation.

• Launch and operation of facilities.

• Customer personnel training.

• Modernization and expansion.

• Maintenance and repair.

Contact US to learn more about our services.

Gas turbine power plants: basics

The 1950s were a period of rapid development of turbines and gas turbine engines.

The beginning of the era of gas turbines dates back to the 18th century, and the first patents for gas turbines were issued at the end of the 19th century.

However, the solutions proposed by Franz Stolze and Charles Curtis were useless for a long time, since the amount of energy required to operate the compressor exceeded the energy at the outlet of the turbine.

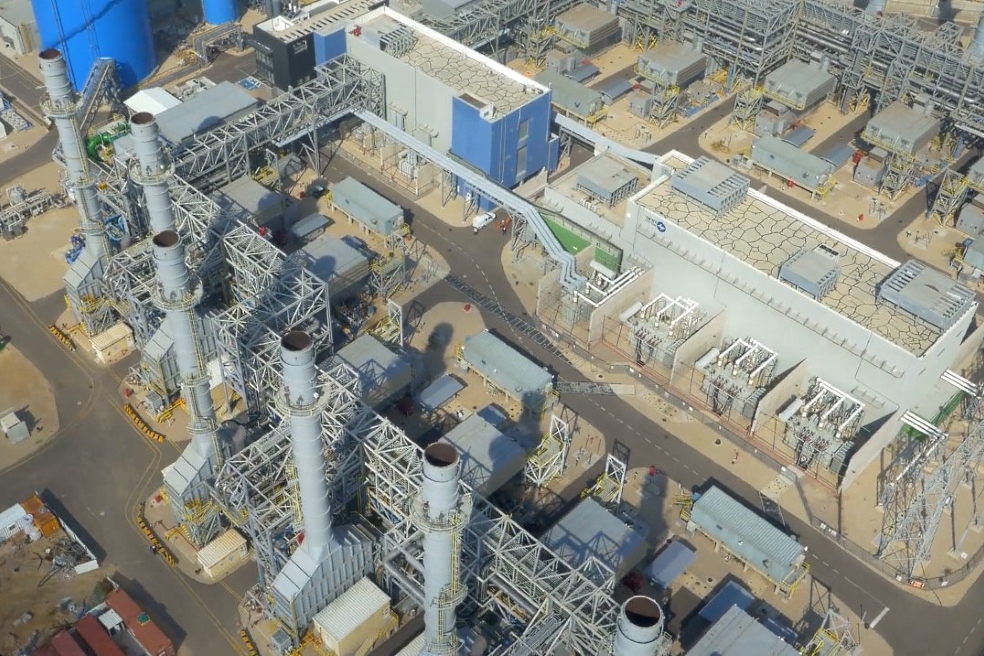

The principle of operation of gas turbine power plants is simple. The intake air is compressed in the combustion chamber of the gas turbine and mixed with fuel (mostly natural gas). This mixture ignites and burns with the formation of gas with temperatures up to 1300-1500 degrees.

Components needed for financing of gas turbine power-plants are below;

• Gas turbine.

• Alternator and its infrastructure.

• Piping and duct systems.

• Air purification systems.

• Automatic control system.

• Electrical substation.

• Service platforms, etc.

This happened largely due to the advanced standardization of components. In the struggle for a market dominated by steam turbines, comprehensive packages of compressors, turbines and controls were proposed to create fully integrated power generation systems.

In addition, advances in new materials and cooling technologies have enabled manufacturers to increase gas temperature, resulting in improved overall system efficiency.

Benefits of financing gas turbine power-plants for the energy sector

These requirements are well met by modern thermal power plants based on gas turbines, which led to an increase in the number of these facilities in power systems in the 1970s. This area is successfully developing today.

The increased interest in the construction of gas turbine power plants has arisen due to the growing instability of energy systems.

Financing for gas turbine power-plants and it’s main feature is their high efficiency and quick start-up.

A reliable and flexible system allows companies to quickly restore power supply in emergency situations, guaranteeing the energy security of large enterprises and entire cities.

High operational efficiency is also the most important factor in the widespread use of these units in the energy sector. An additional argument in favor of gas turbines is the relatively low level of pollutant emissions into the environment.

Equipment supply: gas turbine selection

When choosing equipment for the construction of a gas turbine power plant, our experienced specialists determine the balance of the technical characteristics of each of these elements so that the system meets the requirements of the customer company and current standards as much as possible.

The main structural elements of a gas turbine include an air intake, a compressor, a combustion chamber and the working section itself.

When organizing the procurement of equipment for the construction of gas turbine power plants, it is important to agree on the required technical characteristics of each component of the turbine.

Construction of gas turbine power plants under the EPC contract

With project costs amounting to hundreds of thousands of euros for each megawatt of installed capacity, gas turbine power plants are traditionally considered to be very expensive energy facilities. Bank loans and project financing, technical and legal advice, selection of suppliers and contractors – the responsibility for the smooth implementation of such projects is enormous.

As technology advances, it becomes clear that the construction of gas turbine power plants requires the involvement of numerous engineering teams and the active implementation of innovative technologies at all stages of the project.

Viola Funding Limited is ready to become your reliable assistant in the implementation of large energy projects according to the EPC model.

An EPC (engineering, procurement, construction) contract is sometimes referred to as a turnkey construction.

This is a special form of contractual relationship based on the signing of a single contract with the general contractor, who is fully responsible for the implementation of the project.

Viola Funding Limited and its partners offer financing and engineering services, professional selection and procurement of equipment, as well as turnkey TPP construction.

Financing for gas turbine power-plants and stage of purchasing and supplying equipment includes:

• Drafting requirements.

• Organization and holding of tenders.

• Negotiations with manufacturers and suppliers.

• Acceptance and quality control of equipment.

• Delivery of equipment to the site.

The customer can be sure that turbines, transformers, generators, electronic equipment and all materials required to start construction will be ordered, delivered and paid strictly on time.

The EPC formula has many benefits for the customer.

First of all, it is convenience and confidence that the entire process of construction of a gas turbine power plant must be carried out in accordance with current legislation and technical requirements.

Viola Funding Limited with the present of our high net-worth-angel investors are ready to take full responsibility for the implementation and financing of your ambitious project from the drawing stage to start-up and operation.

Directions of modernization of gas turbine power plants

The first gas turbines had separate compressor and turbine systems. These were ineffective and technologically complex solutions. Currently the most widely used solution is to place the compressor and turbine on the same axis.

One of the directions of modernization of the gas turbine power plant is to increase the fuel combustion temperature, which became possible due to the use of resistant materials and the latest design solutions. Combustion chambers are now designed to minimize NOx emissions.

Aviation gas turbines have always required the smallest size and maximum reliability.

In the power industry, size and weight are no longer an issue.

A more important factor was the reduction in turbine manufacturing costs.

Thus, now we can talk about two different technologies with their own ways of development.

Manufacturers currently offer different types of combustion chambers.

For example, these can be independent devices located outside the structure of the turbine itself. Some of the latest technical solutions are multi-section chambers arranged in a ring around the gas turbine.

Over the past decades, progress in this area has been limited by the thermal properties of the materials from which the first stage of the turbine is made.

Significant progress has also been made in this area. Back in the 1960s, the usual inlet gas temperature was 900 ° C, but already in the 1970s this value increased to 1100 ° C. The currently used solutions allow reaching 1500-1600 ° C.

Recently, the work of gas turbine engineers has mainly focused on the development of new materials that can meet the increasing demands for higher gas temperatures. Research is carried out using unusual materials such as ceramics, which are becoming an alternative to the metals currently in use. Many additional operating procedures are also being investigated to improve efficiency and gas turbines.

An important role is played by computerization and automation of gas turbine power plants, which makes it possible to optimize the load of power units taking into account the current needs of the power grid.

Installation of state-of-the-art hardware and software provides a significant reduction in NOx emissions by 60-80% while increasing operational flexibility without costly measures.

If you are interested in financing for gas turbine power-plants, we will provide you with detailed advice on the key aspects of your project.

eMAIL:[email protected]

Website:https://viola-funding.com/